I know little about colour case, but saw this and wondered if it might be of use to anyone, or a con.

just thought I would put it out there.

the claim is to seal, lacquer, and enhance colour case and protect it.

https://conneticutshotgun.co-colour-enhancement-kit/

bruce.

colour case treatment

-

bruce m

- Posts: 3350

- Joined: Tue Aug 04, 2009 5:25 am

- Location: australia

colour case treatment

ventum est amicus meus

-

bruce m

- Posts: 3350

- Joined: Tue Aug 04, 2009 5:25 am

- Location: australia

-

mdeland

- Posts: 11708

- Joined: Mon Nov 20, 2006 1:47 pm

Re: colour case treatment

I've been using True-Oil for some years and it seems to work rather well. UV light is what makes the colors fade.

-

TexasMac

- Posts: 2365

- Joined: Sun Nov 04, 2007 5:29 pm

- Location: Central Texas

- Contact:

Re: colour case treatment

Here's the corrected link in bruce m's initial posting.

https://connecticutshotgun.co/case-colo ... ement-kit/

Here's some info on the subject from my book on the Browning's.

Wayne

===============================================

I discussed case colors and case hardening with Tom Ivanoff who developed the process used by Miroku. In his opinion the case colors created by using potassium cyanide are more durable than those created by the bone and charcoal process. But regardless of the process used to create them, case colors are sensitive to UV radiation and will eventually fade if exposed to sunlight for extended periods of time.

Harsh chemicals such as solvents and high viscosity penetrating oils can accelerate the process and may result in the complete loss of the colors in periods as short as a few weeks. Some gun owners have used various coatings such as varnish, lacquers, or even fingernail polish to protect the finish. Museums and collectors of high quality firearms have known for some time that the best method to protect metal surfaces, including case colors, is to coat the surface with a good quality non-acidic micro-crystalline wax and store the firearm in a dark and controlled environment. Renaissance Micro-Crystalline Wax Polish is the preferred brand used by museum curators. It’s available from MidwayUSA and Brownells. Since Renaissance Wax is relatively expensive and is not likely to be locally available, a couple of frugal alternatives are Butcher's Bowling Alley Wax and SC Johnson Paste Wax for floors. Butcher’s Bowling Alley Wax is the preferred alternative. It’s a clear paste wax, blended of carnauba and other fine waxes in turpentine and mineral spirits. Samuel Curtis Johnson’s paste wax has been around for close to 120 years and still does a good job protecting wood, leather, plastics and metal. Although I have not tried it, another suggested option is to use Lemon Pledge. But bear in mind that Lemon Pledge contains silicones. It may work fine for protecting metal and wood surfaces but if it soaks in the wood, refinishing or touching up the stock or forearm will likely result in “fish eyes” or small circular imperfections in the surface.

Another technique to protect the case colors is to apply a hard coating such as Brownells’ Metal-Coat Epoxy, a clear, tough, epoxy paint used to protect polished or bead-blasted steel, aluminum or brass surfaces. It’s available in an aerosol can. Brownells advertises that one coat provides superb rust resistance, plus additional coats bond into the base coat for more scratch protection. It’s reported to hold up well to gun oils and solvents although some of today’s more aggressive, “super” bore cleaners may damage it. The soft luster looks great and maintains the beauty of color case hardened steel.

I enjoy shooting and handling my firearms. Therefore, the action will be exposed to ultraviolet rays, body oils, cleaning solvents and oil solutions. I’ll “pick up” a can of Renaissance Wax or Metal-Coat Epoxy one of these days, but until then the case-colored metals on my guns are coated with SC Johnson Paste Wax and stored in a well-controlled environment in a large gun safe. If you handle, shoot, and routinely clean your firearms, there’s no getting around it, the case colors will fade to some extent. The best you can hope for is to substantially slow down the process.

https://connecticutshotgun.co/case-colo ... ement-kit/

Here's some info on the subject from my book on the Browning's.

Wayne

===============================================

I discussed case colors and case hardening with Tom Ivanoff who developed the process used by Miroku. In his opinion the case colors created by using potassium cyanide are more durable than those created by the bone and charcoal process. But regardless of the process used to create them, case colors are sensitive to UV radiation and will eventually fade if exposed to sunlight for extended periods of time.

Harsh chemicals such as solvents and high viscosity penetrating oils can accelerate the process and may result in the complete loss of the colors in periods as short as a few weeks. Some gun owners have used various coatings such as varnish, lacquers, or even fingernail polish to protect the finish. Museums and collectors of high quality firearms have known for some time that the best method to protect metal surfaces, including case colors, is to coat the surface with a good quality non-acidic micro-crystalline wax and store the firearm in a dark and controlled environment. Renaissance Micro-Crystalline Wax Polish is the preferred brand used by museum curators. It’s available from MidwayUSA and Brownells. Since Renaissance Wax is relatively expensive and is not likely to be locally available, a couple of frugal alternatives are Butcher's Bowling Alley Wax and SC Johnson Paste Wax for floors. Butcher’s Bowling Alley Wax is the preferred alternative. It’s a clear paste wax, blended of carnauba and other fine waxes in turpentine and mineral spirits. Samuel Curtis Johnson’s paste wax has been around for close to 120 years and still does a good job protecting wood, leather, plastics and metal. Although I have not tried it, another suggested option is to use Lemon Pledge. But bear in mind that Lemon Pledge contains silicones. It may work fine for protecting metal and wood surfaces but if it soaks in the wood, refinishing or touching up the stock or forearm will likely result in “fish eyes” or small circular imperfections in the surface.

Another technique to protect the case colors is to apply a hard coating such as Brownells’ Metal-Coat Epoxy, a clear, tough, epoxy paint used to protect polished or bead-blasted steel, aluminum or brass surfaces. It’s available in an aerosol can. Brownells advertises that one coat provides superb rust resistance, plus additional coats bond into the base coat for more scratch protection. It’s reported to hold up well to gun oils and solvents although some of today’s more aggressive, “super” bore cleaners may damage it. The soft luster looks great and maintains the beauty of color case hardened steel.

I enjoy shooting and handling my firearms. Therefore, the action will be exposed to ultraviolet rays, body oils, cleaning solvents and oil solutions. I’ll “pick up” a can of Renaissance Wax or Metal-Coat Epoxy one of these days, but until then the case-colored metals on my guns are coated with SC Johnson Paste Wax and stored in a well-controlled environment in a large gun safe. If you handle, shoot, and routinely clean your firearms, there’s no getting around it, the case colors will fade to some extent. The best you can hope for is to substantially slow down the process.

NRA Life (Benefactor & President's Council) Member, TSRA Life Member, NSSF Member, Author & Publisher of the Browning BPCR book

http://www.texas-mac.com

http://www.texas-mac.com

-

mdeland

- Posts: 11708

- Joined: Mon Nov 20, 2006 1:47 pm

Re: colour case treatment

I have been using a bead blast finish for all of my case coloring and rust bluing jobs and it seems to make the color last better. I suspect it is because the textured finish allows more surface area for the oxides/sulfates to adhere to as well as True-oil and gun oil, both of which protect against UV.

The difference between pack coloring and cyanide coloring are so stark in appearence as to not be comparable in my opinion. About as much difference as good rust bluing compared to hot salt bluing, not even in the same class.

I like to texture the finished metal surfaces with 70 grit garnet sand then go over that with glass beads which smooths the rough sanded surface and leaves a flat sheen by rounding off the jagged sand cutting. These micro dents are what hold the color from both blue and case coloring.

I like the texturing also because it knocks down the really Gawdy colors to more subdued tones that original case coloring jobs look like. The color is there but not the shine and it seems to wear better.

The difference between pack coloring and cyanide coloring are so stark in appearence as to not be comparable in my opinion. About as much difference as good rust bluing compared to hot salt bluing, not even in the same class.

I like to texture the finished metal surfaces with 70 grit garnet sand then go over that with glass beads which smooths the rough sanded surface and leaves a flat sheen by rounding off the jagged sand cutting. These micro dents are what hold the color from both blue and case coloring.

I like the texturing also because it knocks down the really Gawdy colors to more subdued tones that original case coloring jobs look like. The color is there but not the shine and it seems to wear better.

-

mdeland

- Posts: 11708

- Joined: Mon Nov 20, 2006 1:47 pm

-

mdeland

- Posts: 11708

- Joined: Mon Nov 20, 2006 1:47 pm

Re: colour case treatment

When learning how to case color some 15 years ago or so, I read many papers on the subject and virtually all of the authors said the finish should be polished for best and brightest colors. I decided to try the bead finish to see how it would turn out and liked the effect so well I never did use a polished surface as suggested.

Oscar Gaddy's writings gave me the most useful information along with Browns double gun works in England. Always something new to try and learn out there on the subject.

Oscar Gaddy's writings gave me the most useful information along with Browns double gun works in England. Always something new to try and learn out there on the subject.

-

mdeland

- Posts: 11708

- Joined: Mon Nov 20, 2006 1:47 pm

Re: colour case treatment

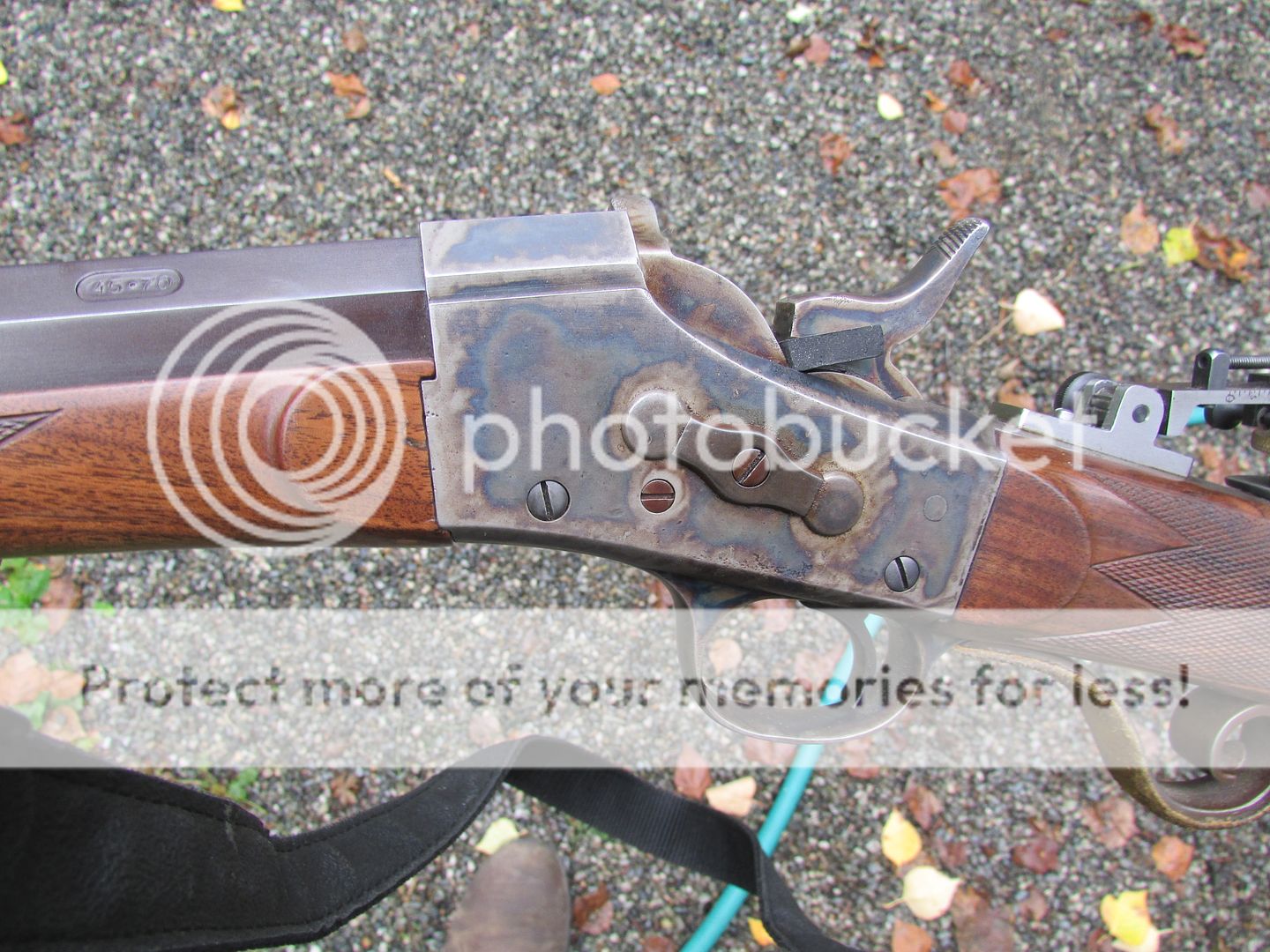

https://i224.photobucket.com/albums/dd2 ... 08.jpgThis one turned out with a lot of the blues showing up.

https://i224.photobucket.com/albums/dd2 ... 010211.jpg

https://i224.photobucket.com/albums/dd2 ... 010211.jpg

- kenny s

- Posts: 775

- Joined: Sat Nov 07, 2015 8:14 am

- Location: Venice FL

Re: colour case treatment

hi midland. I went to light up the photo bucket picts and Norton said it was a 'highly dangerous' website and recommended not to use it.

just FYI...Ken

very nice colors on the roller though.....

I like the bone colors on my Shiloh 74 compared to the old dipped colors.

I have heard that the reason Italy products do not use bone hardening is because the country will not allow the use of bone.

anyone hear of this too?

just FYI...Ken

very nice colors on the roller though.....

I like the bone colors on my Shiloh 74 compared to the old dipped colors.

I have heard that the reason Italy products do not use bone hardening is because the country will not allow the use of bone.

anyone hear of this too?